Rapid Prototyping Services: Transforming Ideas into Reality

In today’s fast-paced business environment, the ability to rapidly bring ideas to life is crucial for success. Rapid prototyping services play a vital role in the product development lifecycle, especially in the metal fabrication industry. This article delves deep into the landscape of rapid prototyping, its benefits, applications, and how companies can leverage these services to stay ahead of the competition.

Understanding Rapid Prototyping

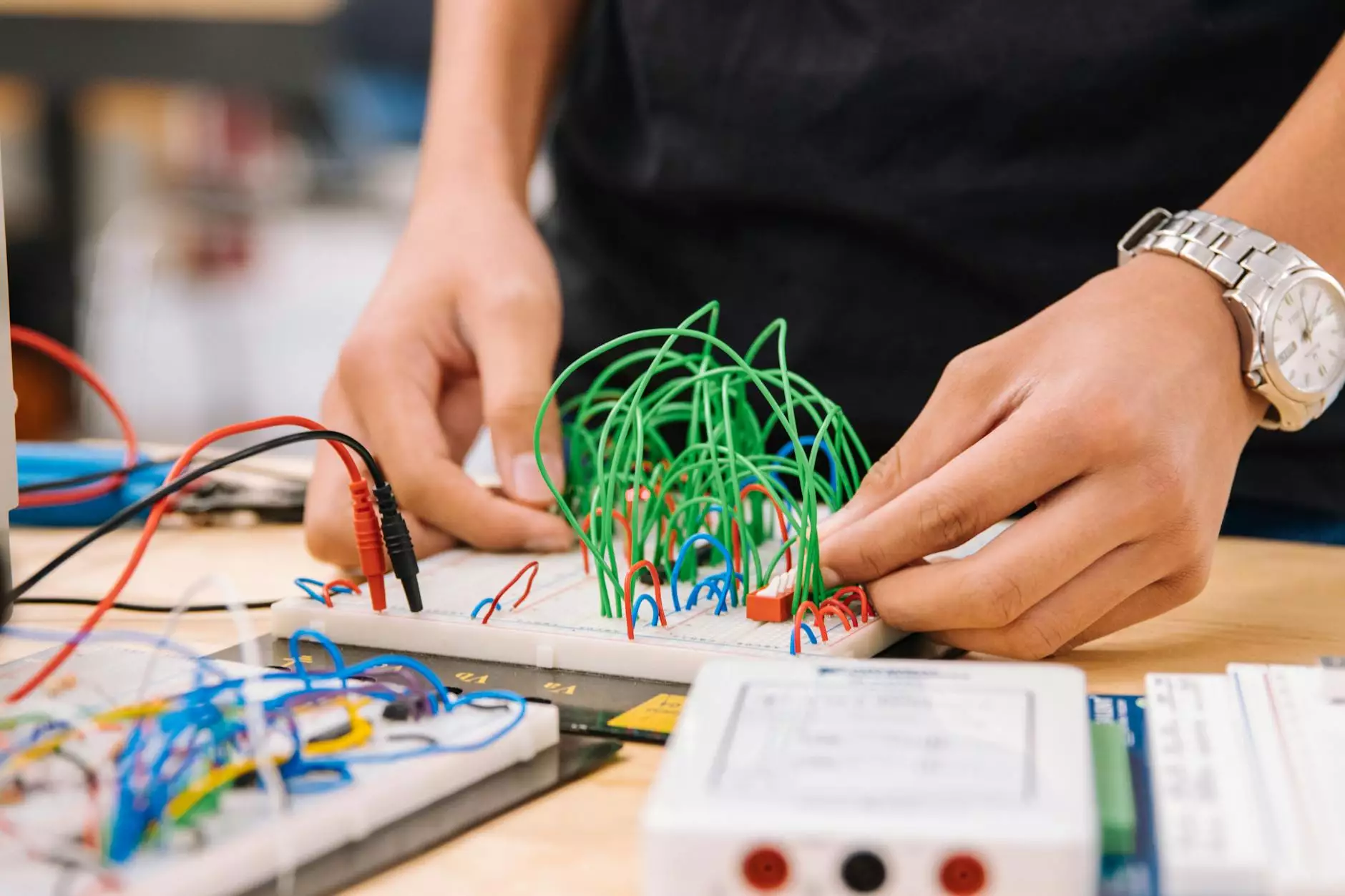

Rapid prototyping is an advanced technique used to quickly create a scale model or prototype of a product. This process allows companies to visualize their ideas, test concepts, and iterate designs efficiently. Many industries use rapid prototyping, but its impact is especially significant in metal fabrication, where precision and speed are paramount.

The Process of Rapid Prototyping

The process of rapid prototyping typically involves several key steps:

- Conceptualization: This is the initial phase where ideas are generated and outlined. It's crucial to assess what the prototype will achieve.

- Design: Using CAD (Computer-Aided Design) software, designers create detailed digital models. At this stage, engineers collaborate to ensure manufacturability.

- Material Selection: Choosing the right materials is essential. Metals, plastics, and composites are often considered based on the properties required for the final product.

- Prototype Production: Using techniques like 3D printing, CNC machining, or vacuum casting, the physical prototype is produced.

- Testing: After the prototype is built, it undergoes rigorous testing to evaluate functionality, durability, and design.

- Iteration: Based on testing results, designers make necessary adjustments to optimize the prototype.

Benefits of Rapid Prototyping Services

Embracing rapid prototyping services offers numerous advantages:

1. Accelerated Time to Market

With rapid prototyping, businesses can dramatically reduce the time it takes to bring a product to market. Traditional product development methods can take months or even years, while rapid prototyping can condense these timelines to mere weeks.

2. Enhanced Design Accuracy

Creating a physical representation of a design helps identify flaws early in the process. This level of accuracy prevents costly changes later on.

3. Cost-Effectiveness

While traditional prototyping methods can be expensive and resource-intensive, rapid prototyping often requires fewer resources. By identifying issues early, companies can save significantly on production costs.

4. Improved Collaboration

With tangible prototypes, teams can engage in better discussions regarding improvements and innovations. Feedback from stakeholders can be integrated seamlessly into design modifications.

5. Increased Flexibility

Rapid prototyping supports iterative processes, allowing businesses to make adjustments quickly in response to market feedback or changing consumer demands.

Applications of Rapid Prototyping in Metal Fabrication

In the domain of metal fabrication, rapid prototyping services are changing how products are designed and manufactured. Below are some key applications:

1. Tooling and Fixture Design

Rapid prototyping can be utilized to create tooling and fixtures that are essential for manufacturing processes. Quick development allows for adjustments based on real-world testing.

2. Product Testing

Before investing in mass production, manufacturers can test product designs and functionality through rapid prototypes. This step is critical for ensuring quality and performance in real-world applications.

3. Custom Parts Production

Rapid prototyping can be used to create custom parts for machines and manufacturing processes quickly. This capability is crucial for industries that require specialized components.

4. Design Verification

By using prototypes to verify designs, companies can ensure that the final product meets all aesthetic and functional requirements before full-scale manufacture.

5. Short-Run Production

In cases where demand is low, rapid prototyping allows for the quick production of parts without the need for expensive molds or tooling, offering a cost-effective solution to short-run manufacturing.

Choosing the Right Rapid Prototyping Service Provider

When seeking rapid prototyping services, particularly within the metal fabrication sector, it's crucial to choose a provider that aligns with your business goals. Here are some factors to consider:

1. Experience and Expertise

Look for companies with a proven track record in rapid prototyping and metal fabrication. Their experience can provide valuable insights during the design and prototyping process.

2. Range of Technologies

Different prototyping services offer various technologies, such as 3D printing, CNC machining, and more. Ensure that the provider utilizes the best technology for your specific needs.

3. Quality Assurance

Verify that the provider maintains rigorous quality control standards to ensure that the prototypes they deliver meet industry specifications and your expectations.

4. Turnaround Time

In business, time is of the essence. Choose a provider that can deliver prototypes quickly, allowing for faster feedback and iteration.

5. Customer Support

Strong customer support can make a significant difference. Find a provider willing to collaborate closely with you throughout the prototyping process.

How Rapid Prototyping Services Benefit Industries Beyond Metal Fabrication

While the advantages of rapid prototyping are particularly evident in metal fabrication, many other industries can benefit:

1. Automotive

The automotive sector uses rapid prototyping to test design concepts for vehicles and components before mass production, ensuring performance and safety standards are met.

2. Aerospace

Aerospace companies utilize rapid prototyping for everything from interior design to production of crucial components, emphasizing precision and reliability.

3. Medical Devices

In the medical field, rapid prototyping allows for the quick development of custom medical devices, ensuring they meet the specific needs of healthcare providers and patients.

Future Trends in Rapid Prototyping Services

The future of rapid prototyping is bright, with numerous technological advancements on the horizon:

1. Advancements in Materials

As new materials are developed, the capabilities of rapid prototyping will expand, allowing for better performance and versatility.

2. Increased Automation

Automation in manufacturing processes can streamline rapid prototyping, reducing costs and time while maintaining quality.

3. Integration with AI

Artificial intelligence can enhance the design process, providing insights and suggestions that improve prototyping efficiency and effectiveness.

Conclusion

In summary, rapid prototyping services are revolutionizing the way businesses approach product development, particularly in metal fabrication. By enabling faster design iterations, improving accuracy, and reducing costs, these services empower companies to innovate like never before. For enterprises looking to thrive in a competitive landscape, investing in reliable rapid prototyping is not just beneficial; it's essential.

Explore more about rapid prototyping services at DeepMould.net.